If you’re scouting for a reliable mouthwash manufacturer, pay attention to a notice: in March, 2024, Top Class Actions reported that Nutraceutical Corporation issued a recall for 102,100 bottles of Heritage Store Hydrogen Peroxide Mouthwash because the product’s ethanol content meant it legally required child-resistant packaging — which the recalled bottles lacked.

The recall covers the wintermint and eucalyptus mint varieties sold in dark brown bottles with white lids, and affects product sold nationwide at stores such as Whole Foods, Fresh Thyme, Mom’s Organic Market, New Seasons and Mother’s Market & Kitchen, as well as online at Amazon, iHerb and HeritageStore.com between October 2010 and December 2023. Consumers were advised to keep affected bottles away from children and to contact the company for a refund or replacement; no injuries had been reported at the time of the notice.

Why lead with this story? For anyone launching a mouthwash brand, this recall is a clear reminder that product safety and packaging compliance aren’t optional — they’re foundational. Choosing the right manufacturing partner can mean the difference between a smooth product launch and an expensive recall that damages customer trust. In the sections that follow, we’ll use this recall as a springboard to outline the practical, documentable checks you should run when vetting potential mouthwash manufacturers.

Packaging & Quality Control

Ensuring both safe packaging and consistent product quality is essential when choosing a mouthwash manufacturer. The Heritage Store recall shows how quickly a lack of child-resistant packaging or poor quality oversight can lead to regulatory issues and damage consumer trust.

Key factors to evaluate include:

- Child-resistant closures: Verify that the manufacturer can produce caps and lids that meet safety regulations, such as the PPPA in the U.S.

- Material safety and durability: Bottles and closures should be non-toxic and able to withstand storage and shipping without leaking or degrading.

- Batch testing and quality checks: Each production batch should be tested for alcohol or hydrogen peroxide levels, pH balance, stability, and microbial contamination.

- Certifications: Look for GMP or HACCP certifications, which demonstrate structured quality management and traceability.

Understanding the right packaging also depends on the type of mouthwash you plan to produce, so reviewing product categories can help make informed decisions. By selecting a mouthwash manufacturer with proven expertise in both packaging and quality control, you minimize the risk of recalls, ensure regulatory compliance, and build consumer confidence in your mouthwash brand.

Production & Logistics

When evaluating a mouthwash manufacturer, it’s crucial to consider both production capabilities and logistical support. Even a safe, well-formulated product can fail to reach customers efficiently without reliable manufacturing and supply chain management.

Key points to assess include:

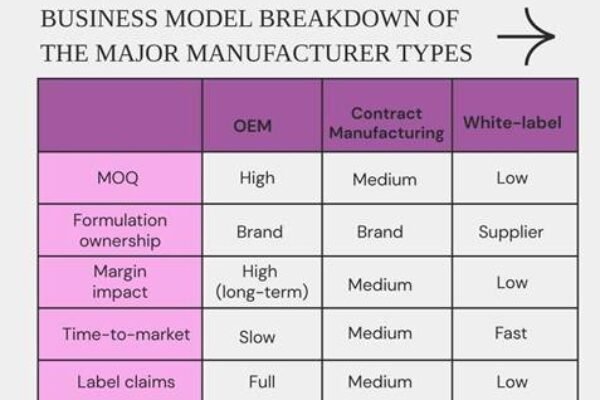

- Minimum order quantity (MOQ) and scalability: Ensure the manufacturer can handle your initial batch and scale production as your brand grows.

- Flexibility: The manufacturer should accommodate formula changes, packaging updates, or seasonal product variations.

- Domestic vs. overseas production: Domestic facilities may offer faster shipping and easier regulatory compliance, while overseas options can reduce unit costs but involve longer lead times.

- Supply chain experience: Confirm the manufacturer can manage shipping, customs, and distribution, and has experience with both retail and e-commerce channels.

Many startups work with OEMs who can accommodate formula tweaks or small pilot runs. To learn more, see our guide on How Mouthwash Manufacturers Meet Customization Demands. Choosing a mouthwash manufacturer with sufficient capacity and logistics expertise helps your business maintain timely product delivery, reduces operational risks, and ensures a smooth customer experience.

Cost & Transparency

When starting a mouthwash brand, understanding the costs involved with a manufacturer is just as important as evaluating quality or compliance. Hidden fees or unclear pricing can quickly eat into your budget and slow down growth.

Here are key points to consider:

Breakdown of costs: Ask for details on mold or tooling fees, packaging, testing, and shipping. This helps avoid surprises later.

Sample and pilot production: Check if small batches are possible and what they cost, which is useful for market testing.

Payment terms and flexibility: Clear milestones and schedules reduce the chance of miscommunication or cash flow issues.

Value-added services: Some manufacturers may assist with labeling, compliance paperwork, or logistics, which can save time and simplify operations.

Working with a transparent mouthwash manufacturer not only makes budgeting more predictable but also fosters a smoother, more trustworthy partnership as your business grows.

Conclusion & Call to Action

The Heritage Store recall clearly shows how quickly a simple packaging oversight can lead to major problems. For anyone starting a mouthwash brand, choosing the right mouthwash manufacturer is more than just picking a production partner—it’s about keeping your customers safe and building trust from day one.

Before you commit, make sure your manufacturer can:

Comply with all relevant regulations and safety standards.

Provide strong packaging and quality control capabilities.

Meet your production needs while handling logistics smoothly.

Be transparent about costs and communication.

Taking these steps early can help you avoid unexpected issues and make the product launch smoother. Reach out to potential mouthwash manufacturers, request samples and certifications, and compare their capabilities carefully. Doing so will give your mouthwash business a solid start, ensuring your products are safe, reliable, and trusted by consumers.